Winter Unveiling

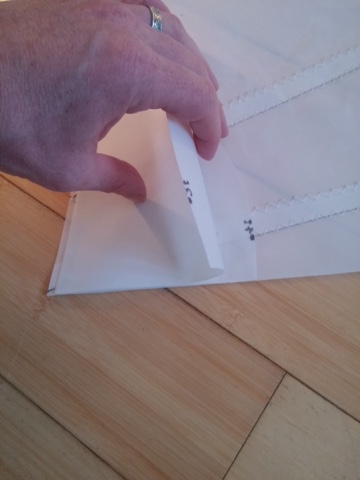

Time for the cover to come off. Today we pulled the tarps, hopefully we are done with this snow stuff. Myles came down and helped. 6 year olds are cool. He helped untie lines and load the support structures back into the car. He even pulled the little tarp off the bow. I was able to get in and open up the cabin. I stored the cushions and sail aboard this winter. I've never done this before but we were in the process of moving. Everything was dry and in good shape and smelled like dryer sheets, which I had thrown down all over the inside of the boat to ward off animals. Our total work time was about and hour before kiddo got too cold and we headed home for some grilled cheese and peep soup. The boat looks good overall, a bit dusty and grimy but nothing a little soap and water followed up with by some wax won't fix. The smell of Dryer Sheets Pulling the last tarp off. Out of Chicken Noodle Soup. How about Coco Peep Soup