Cape Dory Typhoon Genoa part 2

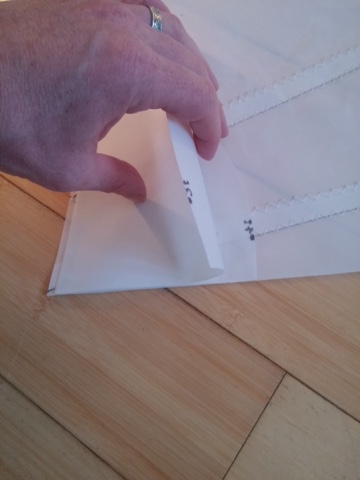

I've been chugging away on the Genoa project bit by bit here. So I'm throwing up some more photos of the project. Corner reinforcement patches. Equal lots of layers. I use my basting tape sparingly, placing it so it is some what off center. This way I will not have to sew through it. I figure 4 or five layers of tape could really add up and I don't need any more layers to sew through. Each corner's vertex is six layers of Dacron thick. Once I got all the layers on, I drew some light lines on the top patch so I could see where to sew. This will secure the whole patch. The clew is one of the most complicated assembly's. To start, I cut and melt the nylon strapping to the right size. The clew will have a steel ring embedded into the corner. The first step is to cut out a space for the ring. I recommend sharp scissors. See earlier (6 layers). It actually cuts pretty easily. The next thing I do is lay out my straps and bast them into place along the foot and le